Flooded Suction Pumps

Flooded Suction Pumps for Challenging Applications

Isle Pump and Dredge specializes in delivering robust flooded suction pumps, including versatile horizontal and vertical models tailored for heavy-duty dredging and pumping tasks in the Bahamas and across global markets. These pumps are designed to excel with abrasive slurries, thick sludge, pastes, high-solid content materials, and other tough-to-handle fluids, even when fluid levels are inconsistent.

Engineered for reliability and long-term durability, our pumps are an ideal choice for industries requiring dependable performance in demanding conditions. From handling viscous materials to overcoming complex flow scenarios, Isle Pump and Dredge ensure your operations run smoothly and efficiently.

Reliable and Affordable Pumping Technology

For rigorous and demanding tasks, the Eddy Pump is a leading choice in dependable pumping solutions. Its cutting-edge design ensures efficient handling of abrasive and viscous materials with zero clogging issues, delivering consistent performance in tough environments.

With minimal maintenance needs, the Eddy Pump is not only reliable but also a cost-effective solution for long-term operations, making it a valuable asset across diverse industries.

Exceptional High-Flow Capabilities

The Eddy Pump outshines conventional pumps with its unmatched efficiency in high-flow and high-pressure operations, serving a broad range of industries with ease.

Anti-Clogging Technology

Designed to handle large debris without blockages, the Eddy Pump ensures safe and efficient performance. Its innovative design minimizes downtime and boosts productivity, even in the most challenging conditions.

Built to Last

Crafted from premium materials such as high chrome alloys, the Eddy Pump offers outstanding durability and resistance, making it the ideal choice for demanding applications where reliability is crucial.

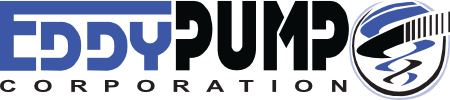

Gravity-Powered Pumping Solutions for Tough Fluids

Flooded suction pumps are a trusted choice across industries like wastewater management, mining, and construction, designed to tackle the toughest fluids and sludge. By leveraging gravity to draw fluid into the pump—thanks to their placement below the fluid source—these pumps ensure reliable and efficient performance.

This gravity-assisted design eliminates the need for pre-priming, combining natural forces with cutting-edge engineering to deliver uninterrupted and highly effective pumping operations in demanding environments.

Horizontal vs. Vertical Pumps: Making the Right Choice

Selecting the ideal pump for your application involves weighing critical factors like fluid density, flow rate, pressure, pumping distance, power source, temperature, pH levels, and resistance to corrosion and erosion.

Both horizontal and vertical slurry pumps have unique strengths tailored to specific operational needs. Choosing a pump constructed with premium materials enhances durability and extends service life, ensuring optimal performance even in the most challenging conditions. Explore our range of pumps to find the best fit for your requirements.

Horizontal Flooded Suction Pumps

Simplified Installation and Maintenance

The straightforward design of horizontal flooded suction pumps ensures quick installation and minimal maintenance, making them a practical choice for a wide range of applications.

Enhanced Flow Capacity

Equipped with larger impellers, these pumps offer superior flow rates, outperforming many other pump types in high-volume applications.

Optimized for Lower NPSH

Ideal for systems with low Net Positive Suction Head (NPSH) requirements, these pumps deliver reliable performance where vertical alternatives might not suffice.

Space Requirements

One consideration is their larger footprint, as horizontal designs require more installation space compared to vertical configurations.

Key Features of Vertical Flooded Suction Pumps

Space-Saving Design

With their compact and streamlined structure, vertical flooded suction pumps are ideal for installations in tight spaces or areas that are difficult to access.

Superior Efficiency

These pumps excel in applications requiring substantial surface lift, delivering reliable and energy-efficient performance even in demanding conditions.

Flexible and Versatile

Their unique design allows them to be suspended or directly inserted into materials, providing unmatched versatility for a wide range of pumping operations.

Maintenance Considerations

While highly effective, these pumps may pose greater challenges for repairs and maintenance compared to other pump designs, requiring specialized expertise.

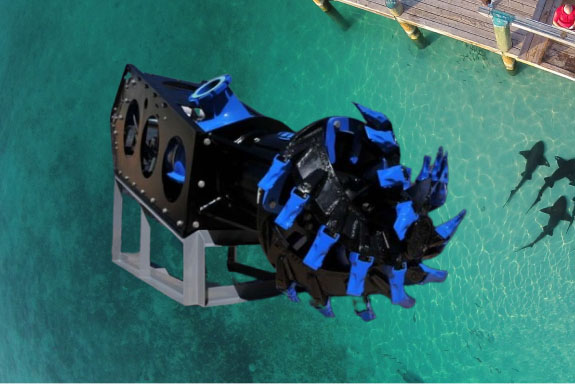

The semi-automated dredge is a space-saving solution, requiring only 650 square feet of operational area. Designed for efficiency, it consumes less energy while handling deeper water levels without the need for onboard operators.

Equipped with three or four electronically controlled winches, the dredge ensures precise navigation along predefined dredging paths, along with seamless pump depth control and RPM adjustments.

Globestar’s innovative cable deployment system, protected by patent, enables operation at depths of up to 100 feet. Its streamlined design, free of internal structures, allows for continuous 24-hour operation, making it an ideal choice for demanding dredging projects.

Key Considerations for Selecting a Flooded Suction Pump

Pump Design

Choose a pump specifically engineered for flooded suction processes. It should have a robust structure capable of withstanding harsh fluids while ensuring optimal performance.

Flow Capacity

Flooded suction pumps are ideal for handling high solid concentrations in fluids or slurries. They efficiently transport liquids containing dirt, grit, or particles, making them suitable for demanding applications.

Minimized Obstructions

The pump’s design should allow smooth solids passage, reducing the likelihood of blockages. This helps minimize maintenance and repair needs, ensuring consistent operation.

Enhanced Efficiency

Submersible suction pumps are highly efficient, with reduced clogging risks and reliable flow performance, making them ideal for heavy-duty tasks.

Durable Construction

Look for pumps made from wear-resistant materials, such as stainless steel, cast iron, or high-density polyethylene. These materials ensure longevity and sustained performance in abrasive environments.

Cost-Effectiveness

Flooded suction pumps are stable and economical solutions for handling challenging fluids. Ensure the pump’s flow rate matches the requirements of your application to avoid inefficiencies.

Head Pressure

Evaluate the vertical lift required (head pressure) to ensure the pump can meet the demand without compromising performance or durability.

Material Compatibility

Verify that the pump material is compatible with the type of fluid being handled. Corrosive or abrasive fluids may require specific materials for extended operational life.

Engine Power and Efficiency

Consider the motor’s power and efficiency. High-flow volumes or viscous fluids may require a more powerful motor for optimal performance.

Leak Prevention

Seek models with tightly sealed couplings to prevent leaks and maintain operational efficiency.

Installation and Maintenance

Choose a pump with straightforward installation and accessible maintenance features. Ensure spare parts are readily available to reduce downtime.

Safety Features

Prioritize pumps with built-in safeguards such as overload protection, thermal sensors, and guards to prevent damage and enhance reliability.

Manufacturer Reputation

Select a pump from a manufacturer known for producing durable and dependable products. A trusted brand with proven expertise ensures quality and peace of mind.

Key Benefits of Advanced Pump Technology

Superior Solids Handling

Designed for fluids with high solid content, these pumps excel at managing slurries and liquids containing particles, debris, or abrasive materials, ensuring reliable performance in demanding conditions.

Reduced Risk of Clogging

Advanced pump designs allow for seamless solids passage, preventing blockages and minimizing the need for frequent maintenance or costly repairs.

Optimized Efficiency

Engineered for improved flow management, submerged suction pumps deliver higher throughput rates, enhancing overall operational efficiency and reducing downtime.

Exceptional Durability

Built from high-quality, wear-resistant materials, these pumps are designed for long-term use, offering superior durability even in harsh environments.

Economical and Reliable

Flooded suction pumps provide a cost-effective solution for handling challenging fluids. Their combination of affordability, efficiency, and reliability makes them an ideal choice for various industrial applications.

Our pump models

Model | Diameter | Power | GPM Flow | Head |

DSP/HD 3000 | 3 inches | 43 HP | 100 – 780 | up to 130 feet |

DSP/HD 4000 | 4 inches | 43 HP | 250 – 1200 | up to 200 feet |

DSP/HD 4000 | 4 inches | 115 HP | 250 – 1200 | up to 200 feet |

DSP/HD 6000 | 6 inches | 115 HP | 450-2000 | up to 200 feet |

DSP/HD 6000 | 6 inches | 173 HP | 450-2000 | up to 200 feet |

DSP 8000 | 8 inches | 550 HP | 1600 – 5000 | up to 240 feet |

DSP 10000 | 10 inches | 550 HP | 1600 – 5000 | up to 240 feet |

DSP 12000 | 12 inches | 700 HP | 2600 – 7300 | up to 180 feet |

Comprehensive Benefits of Managing Slurries and Complex Liquids

Self-Priming Efficiency

Self-priming pumps are engineered to handle fluid suction without requiring external priming devices or additional setup steps. This design simplifies the assembly process and minimizes start-up delays, allowing for quicker deployment in various applications.

Exceptional Durability

Constructed with high-grade materials and equipped with advanced sealing mechanisms like o-rings, mechanical seals, and liners, these pumps offer robust resistance against wear, corrosion, and abrasive fluids. Their durability ensures dependable performance and longevity, even in environments with highly corrosive or gritty substances.

Versatile Applications

Submersible suction pumps are versatile enough to manage fluids across a broad range of consistencies, from liquids with heavy solid content to thick sludge. They are widely used in industries such as mining for ore transport, construction for dewatering, water treatment for sludge handling, and industrial manufacturing processes requiring precision fluid management.

Reduced Maintenance Requirements

Thanks to their rugged construction and efficient operational design, these pumps require minimal servicing. This feature not only reduces downtime but also significantly lowers maintenance costs over their lifecycle, making them a cost-effective choice for high-demand environments.

Reliable and Steady Performance

The flooded suction configuration ensures a continuous and consistent flow of fluid, effectively preventing interruptions caused by airlocks or cavitation. This stable operation reduces system vibrations and wear, enhancing both efficiency and equipment lifespan.

Related Equipment

Dredging Equipment

Check out our top-quality dredging equipment, made for projects like removing sand, gravel, and minerals in the Bahamas. Our machines use advanced technology to work efficiently and help you save money, whether for small projects or large industrial jobs. Our equipment is made from strong, high-quality materials to last a long time and handle tough jobs. It’s easy to use and maintain, so you can focus on getting the job done. No matter the size of your project, our dredging tools are built to deliver great results every time.